Next-level packaging, right here in the USA.

Shorter lead times. Better service. Zero tariffs. 99.53% customer satisfaction.

Your complete container solution, locally. COMPAX molds and decorates bottles, jars, and caps in our 200,000 sq ft manufacturing facility in Salt Lake City, UT.

With over two decades of manufacturing experience, our team of engineers, quality control experts and managers ensure your project is delivered on-time without error.

Certified for Excellence

Quality Management

Ensuring consistent, high-quality production with rigorous process control.

Environmental Management

Minimizing our environmental impact through sustainable manufacturing practices.

Occupational Health & Safety

Protecting our team with globally recognized safety standards and protocols.

Extrusion Blow Molding

1oz to 2.5 gallon HDPE Bottles, Vitamin Packers, Wide-Mouth Jars, Handleware and more

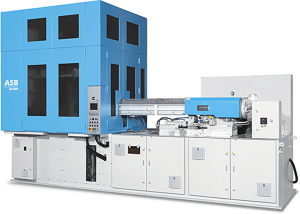

Injection Blow Molding

2oz to 10oz PET and HDPE Bottles, Jars, Vitamin Packers and more

Injection Molding

2g to 100g Closures, Disc Top Dispensing Closures, Wide-Mouth Jar Closures, Halo Caps, Jars, Overcaps and more

Co-Extrusion

- Dual Color

- Soft Touch

- Dual Resin / PCR Outside

Color

- Precise Custom Color Matching

- Metallic + Pearl Finishes

In-Mold Matte & Polish

- High polish for shine and gloss

- In-mold matte for a tactile matte

Emboss/Deboss

Custom look, minimal tooling cost

Automatic Assembly

Assembly of custom disc top closures

Custom Molding

Almost any shape, size, color and material. Have a request? Let’s talk it through.

Color & Finish

- High polish

- In-mold matte

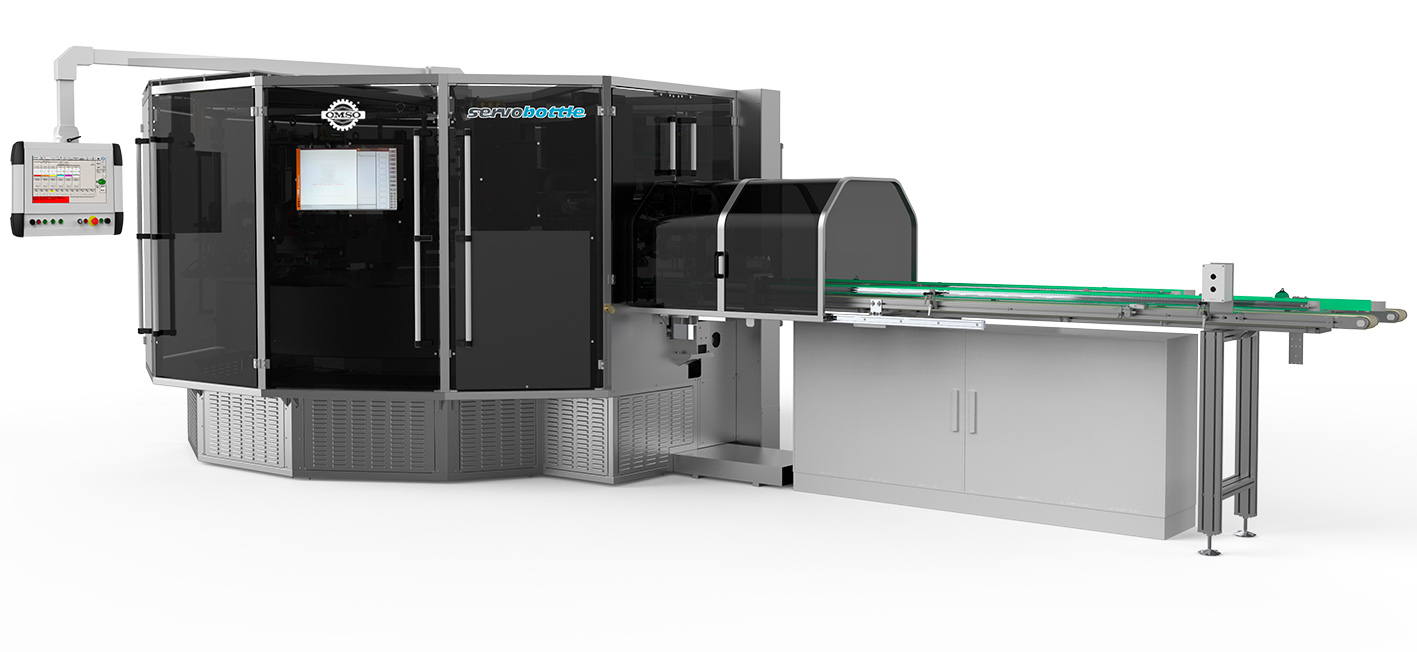

Silkscreen

- Up to 5 passes (colors)

- Servo-driven registration

Labeling

- High Speed Label Application

- Top lid labeling

Cap Lining

- Molded-in Halo Liner from 2 shot injection molding

- In-house punch induction lining

Stretch Blow Molding

1oz to 2 gallon PET Bottles, vitamin packers, and jars

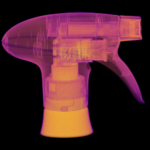

COMPAX Quality Lab

Create better products and take control of your component manufacturing. COMPAX uses CT scan technology and powerful, cloud-based analysis software to solve tough engineering challenges at every stage of the product development process. Tell us the problem, send us samples, and we can help diagnose and resolve.

CT Scanning Benefits

COMPAX uses CT scanning technology to speed R&D timelines and stay ahead of quality. The capability to scan a component and create a 3D drawing for manipulating, prototyping, or tooling, puts COMPAX clients weeks to months ahead of competitors on new tool builds. We’re able to quickly problem solve, refine designs, and perfect our production with scanning technology.

Dedicated to quality since ’97.

Our production floors operate under cGMP and a comprehensive Quality Management System (QMS) built on ISO 9001 standards. We are also ISO 14001 and ISO 45001 certified, reinforcing our commitment to environmental responsibility and workplace safety. From a documented pre-production approval process to a custom-built system that tracks individual customer requirements, our team is equipped to meet every request with precision.

AI-Powered Quality Control

COMPAX implements vision control systems as customer requirements demand, using recipes that build and learn on each other to determine acceptable and rejected containers to pack and ship.

sustainability

sustainability

sustainability

sustainability

sustainability

Energy & Resource Efficiency

COMPAX places a strong emphasis on environmental responsibility and sustainability. Our unwavering commitment revolves around minimizing our carbon footprint, and we do so by diligently working to decrease the ratio of power consumed to the weight of finished goods shipped on an annual basis. Our journey toward sustainability is marked by an ongoing pursuit of enhanced energy efficiency and operational excellence.

At COMPAX, we recognize that the packaging industry plays a significant role in environmental impact, from resource consumption to waste generation. In response to these challenges, we have set ambitious goals to reduce our energy consumption per unit of product shipped, year after year. This commitment extends beyond mere compliance with regulations; it is a pledge to proactively contribute to a more sustainable future.

Key elements of our sustainability efforts include:

- Energy Efficiency Innovations: We invest in cutting-edge technologies and processes that optimize our energy usage throughout the entire production cycle. We continuously seek ways to minimize energy waste and improve efficiency.

- Material Sourcing: We are dedicated to sourcing eco-friendly materials whenever possible, including recycled and recyclable options. Our choice of materials not only aligns with sustainability goals but also supports our commitment to reducing the weight of finished products, thus lowering shipping-related emissions.

- Transportation Optimization: COMPAX actively collaborates with logistics partners to streamline transportation routes and methods. We aim to reduce the carbon footprint associated with shipping our products to customers and minimize fuel consumption.

- Waste Reduction and Recycling: We implement robust waste reduction and recycling programs within our facilities. By responsibly managing waste streams, we not only reduce our environmental impact but also contribute to a circular economy.

- Employee Engagement: We empower our workforce to actively participate in our sustainability initiatives. Through training and awareness campaigns, our employees are encouraged to identify and implement energy-saving practices and contribute ideas for continuous improvement.

- Supplier Collaboration: We collaborate closely with our suppliers to ensure they share our commitment to sustainability. Together, we work to minimize the environmental impact of the materials and components we source.

- Lifecycle Assessment: COMPAX conducts comprehensive lifecycle assessments of our products to identify areas for improvement. This approach allows us to make informed decisions about design, materials, and processes.

- Transparency and Reporting: We maintain transparency in our sustainability efforts by regularly reporting progress and sharing our successes and challenges with our stakeholders. This transparency encourages accountability and fosters trust.

Raw Material Recycling Program

In line with our sustainability initiatives, we have implemented a comprehensive recycling program that ensures the responsible management of our raw material scrap. Our pledge is to recycle 100% of our raw material scrap, whether it is processed in-house or through trusted external partners.

Here’s an in-depth look at our recycling program:

Internal Recycling

Within our own facilities, COMPAX has established state-of-the-art recycling processes that efficiently manage and repurpose raw material scrap. This includes utilizing advanced machinery and technology to collect, sort, and process scrap materials generated during our manufacturing processes. These materials are carefully segregated and transformed back into usable resources, reducing waste and minimizing the environmental impact associated with raw material production.

External Recycling Partnerships

In addition to our in-house recycling efforts, COMPAX collaborates with external recycling partners who share our commitment to sustainability. These partnerships extend our recycling capabilities and allow us to responsibly manage raw material scrap that may not be suitable for internal processing. By working with reputable recycling companies, we ensure that these materials are diverted from landfills and are instead transformed into valuable recycled products.

Closed-Loop Recycling

Our dedication to sustainability extends to closed-loop recycling whenever possible. This means that recycled materials are often reincorporated into our production processes to create new packaging solutions. This not only reduces the demand for virgin raw materials but also conserves resources and lowers energy consumption, contributing to a more circular and eco-friendly economy.

Waste Reduction and Efficiency

COMPAX continuously seeks ways to optimize our manufacturing processes to generate less raw material scrap in the first place. By reducing waste at the source, we not only minimize the need for recycling but also decrease our overall environmental footprint.

Environmental Stewardship

Our recycling efforts are in alignment with our broader environmental stewardship goals. By responsibly managing raw material scrap, we reduce greenhouse gas emissions, conserve natural resources, and contribute to a more sustainable future for our planet.

Extensive Sustainable Stock Options

COMPAX is steadfast in its commitment to empowering customers with the knowledge and resources needed to protect our planet and embrace sustainable practices. Beyond merely offering products, we actively stock an array of sustainable packaging options, ensuring that our customers have the means to make environmentally responsible choices.

Educational Initiatives

At COMPAX, we understand that informed decisions are the cornerstone of sustainability. We invest in educational initiatives that empower our customers with the knowledge to make eco-conscious choices. This includes providing information about the environmental impact of various packaging materials and methods, as well as offering guidance on sustainable packaging solutions that align with their specific needs.

Sustainable Product Portfolio

We take pride in curating a comprehensive range of sustainable packaging products. This portfolio includes options made from recycled materials, biodegradable and compostable alternatives, and packaging designs that optimize material use, reduce waste, and minimize carbon footprints. By offering these sustainable choices, we enable our customers to align their packaging strategies with their sustainability goals.

Customized Sustainability Solutions

COMPAX understands that one size does not fit all when it comes to sustainability. We work closely with our customers to develop customized packaging solutions that meet their unique environmental objectives. Whether it’s reducing plastic usage, optimizing packaging for transportation efficiency, or exploring innovative materials, we collaborate to find the most sustainable approach.

Environmental Impact Assessments

To help our customers make informed decisions, we provide detailed assessments of the environmental impact associated with various packaging options. This includes life cycle assessments (LCAs) that consider the entire journey of a package, from raw material extraction to end-of-life disposal. By quantifying environmental impacts, we assist customers in choosing the most eco-friendly packaging solutions.

Continuous Research and Innovation

COMPAX is committed to staying at the forefront of sustainable packaging innovations. We invest in research and development to explore emerging technologies and materials that can further reduce the ecological footprint of our products. This commitment to innovation ensures that we’re always ready to offer the latest in sustainable packaging solutions.

COMPAX Catalog

Get your project rolling

Explore our catalog of stock items and customize with unlimited decoration options.

Careers @ COMPAX

We're always looking for talent!

Got what it takes to work with us? Explore career openings, or drop us your resume in our career portal.